-

COMPOSITE MILL LINERS

As grinding mills are made increasingly larger, however, operating mills of increasing diameter presents significant liner service life challenges.

To meet these challenges, SHANVIM offers composite mill liners which combine a proprietary wear resistance steel and high pressure molded rubber.

The abrasion resistance steel alloys have approximately double the service time of a standard rubber liner, and the rubber structure absorbs impact from large rocks and grinding media. SHANVIM composite mill linings combine the most desirable properties of rubber and steel to maximum advantage.- -

CAVITY WEAR PLATE-VSI CRUSHER PARTS

Tip / Cavity Wear plates are designed to protect the outside edges of the rotor against excited particles in the crushing chamber. As the rotor spins, it impacts against particles that have rebounded from the chamber build-up after their initial exit from the rotor. As the TCWP are the furthest wear part from the centre, and on the leading faces of the rotor, then they are most susceptible to this type of wear.

These parts are positioned in two places on the rotor, firstly they are put on top of the rotor tips to protect the vulnerable areas of the parts, and secondly on the other side of the rotor port to protect this leading edge from wearing away and compromising the rotors efficiency. -

IMPACT PLATE-LOST FOAM CASTING

Impact plate is one of the primary wearing parts of an impact crusher. Impact plate made in shanvim® has brought owners huge maintenance cost savings.

A higher initial hardness explains the extended service life compared with the typical manganese steel used. Mn steel is so-called deformation hardening steel, with an initial hardness of ~280 HB. Some users have more than doubled the service life after switching to shanvim®. The ease of welding and hardcover is another reason behind successful upgrades to shanvim®. -

RACK SHOE OF CUSTOMIZED ALLOY STEEL EXCAVATOR BULLDOZER

Rack shoes are widely used in crushers, excavators, bulldozers, crawler cranes, pavers and other construction machinery. Shanvim crawler shoes use processing technologies such as profile blanking, drilling (punching), heat treatment, straightening and painting. The crawler shoes produced by Shanvim can complete station adjustment in a short time and enter the working state at any time. This can reduce the handling operation of materials and facilitate the coordination of all auxiliary mechanical equipment. Through wireless remote control, the crusher can be easily driven to the trailer and transported to the operation place. -

UPPER AND LOWER WEAR PLATES-VSI CRUSHER PARTS

These wear plates are designed to protect the upper and lower faces of the inside of the rotor from the feed material as it passes through the rotor (the material build-up protects the sides).

Wear plates are kept in place using the centrifugal force of the rotor as it is spinning, there are no nuts and bolts, only some clips for the plates to slide under. This makes them easy to change and remove.

The lower wear plates generally wear more than the upper wear plates due to under utilization of the rotors maximum throughput and the use of an incorrectly shaped trail plate. -

STEEL BALLS FOR BALL MILL AND ROD MILL

High Manganess Casting Material Chemical Composition Code Elem. C Mn Si Cr Mo P S ZGMn13-1 1.0-1.45 11.0-14.0 0.30-1.0 - - 0.09 0.04 ZGMn13-2 0.90-1.35 11.0-14.0 0.30-1.0 - - 0.09 0.04 ZGMn13-3 0.9-1.35 11.0-14.0 0.30-0.8 - - 0.09 0.04 ZGMn...

40 60 80 100 120 high/medium/low chrome ball mill liners. -

VSI CRUSHER PARTS-DISTRIBUTOR PLATE/DISC

VSI crushers have many different wear parts inside the Rotor. Including:

Rotor Tips, Back-up Tips, Tip / Cavity Wear Plates to protect all areas of the exit ports

Upper and Lower internal wear plates to protect the inner body of the rotor

Internal distributor plate to receive initial entry impact and distribute the material to each port

Feed Tube and Feed Eye Ring to guide the material centrally into the rotor

Internal Trail plates to maintain rotor stone beds formed during operation -

BOWL LINER-CONE CRUSHER ORIGINAL PARTS

Cone crusher is widely used in metallurgy, construction, mining and other industries, and can be used as secondary crushing or tertiary and tertiary crushing. Various consumable parts of hydraulic cone crusher, compound cone crusher, spring cone crusher are collectively called cone crusher accessories. -

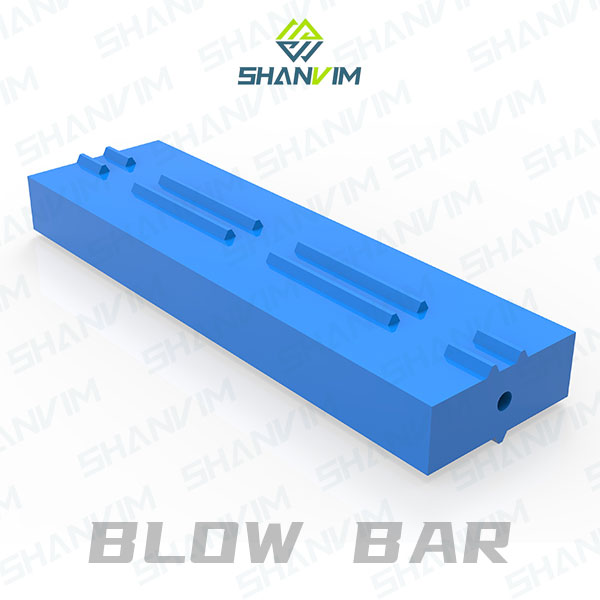

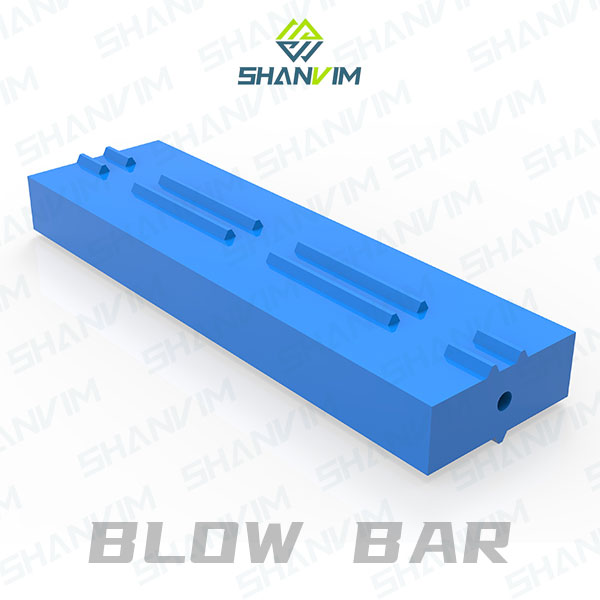

BLOW BAR FOR CEMENT INDUSTRY

Shanvim’s blow bars and impact plates are widely used on mining, construction, chemical, cement and metallurgical industry. Our impact parts have a service life 50~100% longer than those made of traditional high chromium iron. -

BLOW BAR-IMPACT CRUSHER WEAR PARTS

Impact crusher is one of the widely used crushers. The parts of impact crusher are an important part of impact crusher and need to be replaced on schedule; It is also known as vulnerable parts of impact crusher in the industry. Shanvim can provide high quality wear-resistant parts for various types of impact crushers, such as impact breaking hammer, impact block, impact liner, sieve plate, check plate, etc. it can also manufacture products of different materials according to the drawings provided by customers. -

JAW PLATE MADE OF HIGH MANGANESE

High manganese steel is the traditional material of jaw plate , because it has good toughness and good deformation hardening ability. According to the element content, Mn13%,Mn13%,Cr2%,Mn18%,Mn18%Cr2%,Mn22%Cr2%.Or according to the special ingredients under working conditions, the jaw plate of the new micro alloy high manganese steel jaw crusher produced by Zhejiang Shanvim has fine workmanship, rigorous ingredients and in place heat treatment. -

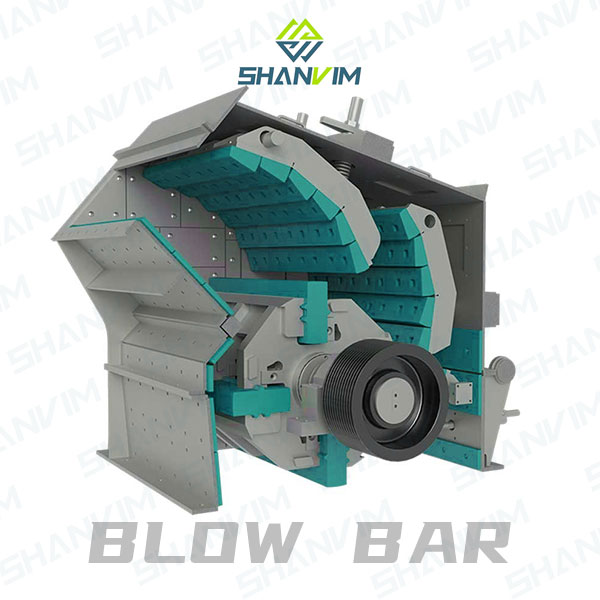

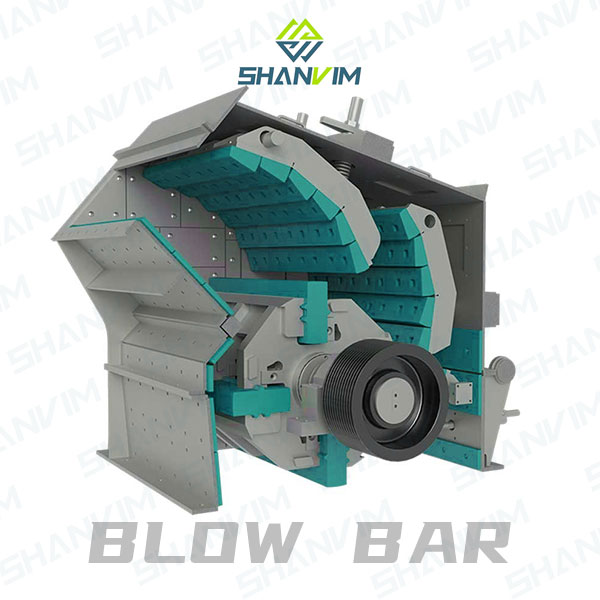

IMPACT CRUSHER WEAR SPARE PARTS-BLOWBAR-IMPACT BLOCK-LINER PLATE

Impact Crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, motor drives the rotor rotates at a high speed. When the material enters the impact area of the blow bars, it hits and breaks with the blow bars on the rotor, and then it is thrown to the counterattack device which is called breaker plates and broken again, and then rebounds from the breaker plates. Return to the rotor action area to re-crush.

This process is repeated. The material enters the first, second, and third impact chambers from large to small, and is repeatedly crushed until it is crushed to the required size and discharged from the discharge port.