-

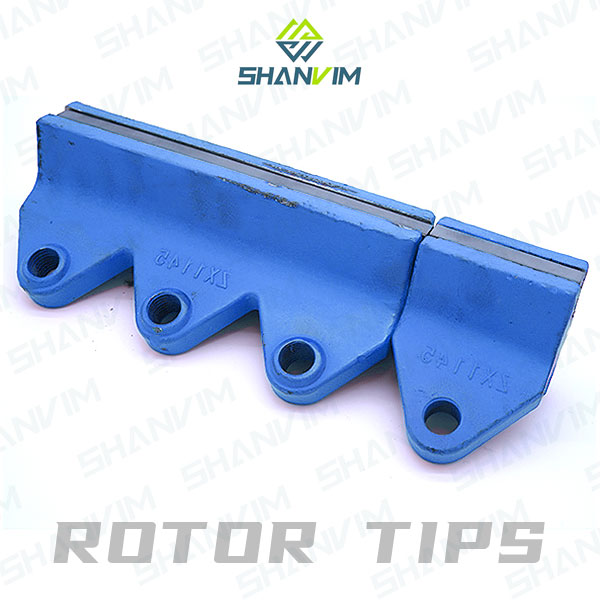

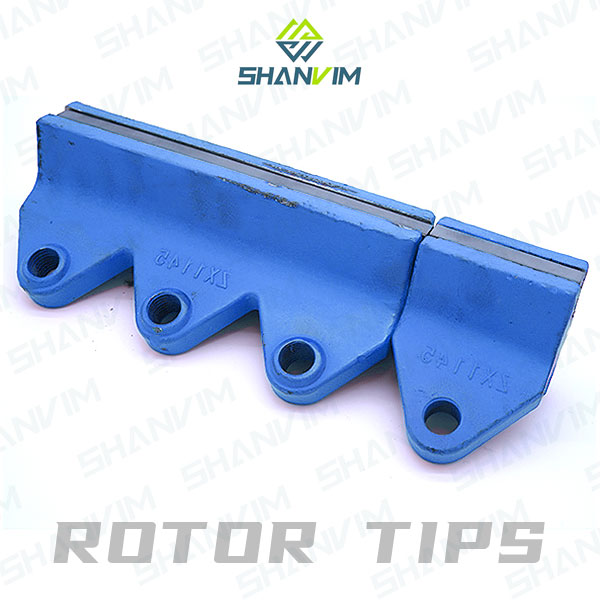

TIP AND BACK-UP TIP

The Rotor tips are the last thing to touch the feed material as it exits the rotor. They have a Tungsten insert that improves wear life. We often use the life of the tips as a reference point for the other rotor wear parts.

The back-up tip is designed to protect the rotor if and when a rotor tip gets broken or worn out. When this happens the Tungsten insert in the rotor tip has split and is now letting feed material run against the Tungsten insert of the back-up tip.The back-up tip has a small Tungsten insert in it that will last for about 8 -10 hours of wear in normal operation. If this backup is broken again, or it wears out then the feed material can seriously damage the rotor due to abrasion. -

CAVITY WEAR PLATE-VSI CRUSHER PARTS

Tip / Cavity Wear plates are designed to protect the outside edges of the rotor against excited particles in the crushing chamber. As the rotor spins, it impacts against particles that have rebounded from the chamber build-up after their initial exit from the rotor. As the TCWP are the furthest wear part from the centre, and on the leading faces of the rotor, then they are most susceptible to this type of wear.

These parts are positioned in two places on the rotor, firstly they are put on top of the rotor tips to protect the vulnerable areas of the parts, and secondly on the other side of the rotor port to protect this leading edge from wearing away and compromising the rotors efficiency. -

UPPER AND LOWER WEAR PLATES-VSI CRUSHER PARTS

These wear plates are designed to protect the upper and lower faces of the inside of the rotor from the feed material as it passes through the rotor (the material build-up protects the sides).

Wear plates are kept in place using the centrifugal force of the rotor as it is spinning, there are no nuts and bolts, only some clips for the plates to slide under. This makes them easy to change and remove.

The lower wear plates generally wear more than the upper wear plates due to under utilization of the rotors maximum throughput and the use of an incorrectly shaped trail plate. -

VSI CRUSHER PARTS-DISTRIBUTOR PLATE/DISC

VSI crushers have many different wear parts inside the Rotor. Including:

Rotor Tips, Back-up Tips, Tip / Cavity Wear Plates to protect all areas of the exit ports

Upper and Lower internal wear plates to protect the inner body of the rotor

Internal distributor plate to receive initial entry impact and distribute the material to each port

Feed Tube and Feed Eye Ring to guide the material centrally into the rotor

Internal Trail plates to maintain rotor stone beds formed during operation