-

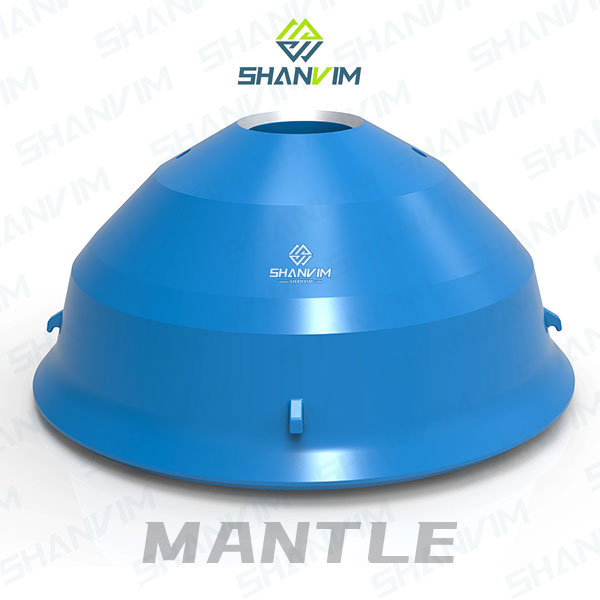

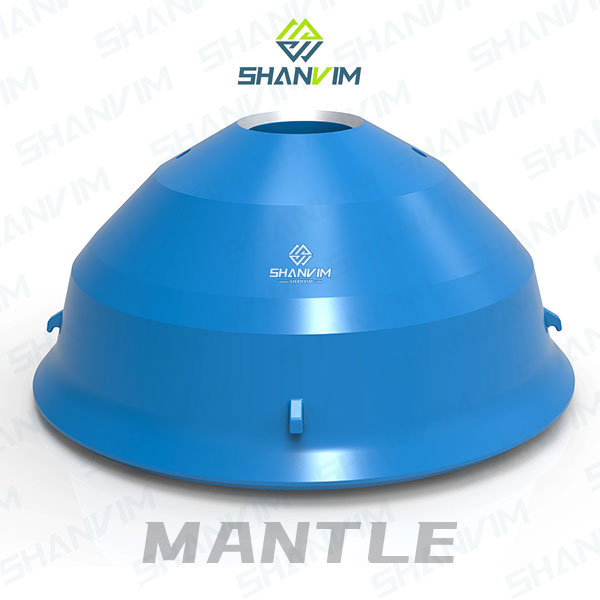

HIGH MANGANESE STEEL ACTIVE BOWL LINER

The material of SHANVIM concave and mantle: Mn13Cr2, Mn14Cr2, Mn18Cr2, Mn22Cr2, ASTM A128 Gr A & B2 & B3, BS 3100 Gr BW10, SABS 407 Type 1 & 2, SABS 407 Type 6, GX 130 MnCr 20.3,ASTM A128 Gr D, SABS 407 Type 4, ASTM A128 Gr E, SABS 407 Type 5

Through special heat-treatment process and With special chemical composition, SHANVIM cone mantle & bowl liner has a service life 30% longer than those of traditional high manganese steel! -

MANTLE-CONE CRUSHER PARTS FOR SALE

When it comes to replacement cone crusher parts, SHANVIM has been crushing the market for decades. If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed and warranted replacement parts for your cone crusher, your search ends with SHANVIM MACHINERY – Your Replacement Cone Crusher Parts SuperStore. SHANVIM manufactures replacement components of many brand crushers all over the world. -

HIGH CHROMIUM METAL CERAMIC BLOW BARS

Metal Matrix Composites (MMC) Ceramic Blow Bars also known as Cearmic Blow Bars, include:

Chrome Iron Matrix with Ceramic Composites Blow Bars;

Martensitic Alloy Steel Matrix with Ceramic Composites Blow Bars;

Ceramic Blow Bar is one of the most common impact crusher wear parts. It combines the high resistance of the metal matrix with extremely hard ceramics.

Porous preforms made of ceramic particles are produced in the process. The metallic molten mass penetrates into the porous ceramic network. -

MANTLE-TIC INSERT ALLOY STEEL

The use of low-cost high-manganese steel or super-high manganese steel for large wear-resistant parts of the base material, composite parts in their work inlaid carbide, the bimetal composite wear parts wear surface has excellent wear resistance, non-wear Mask has excellent plasticity and impact toughness, reducing the wear of the matrix of high manganese steel, so that the mantle and concave greatly increased service life. -

BOWL LINER-MINING EQUIPMENT PARTS

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.

The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

SHANVIM® cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

-

MANTLE-GOOD AFTER-SALES SERVICE

Plenty of 13%-22%Mn premium quality Mn Liners in SHANVIM to suit crushers. Aftermarket professionals providing crushing and mining solutions to mining, aggregate and recycling industries!

SHANVIM provides a complete offering, for both standard and engineered-to-order parts, ensuring you have the availability and support required. We provide flexible options to secure parts on a one-time basis, as a turn-key service, or anywhere in between. -

HIGH MANGANESE BLOW BAR

Blow bar is the main spare part of impact crusher. There are high manganese blow bar,high chrome blow bar. The material depends on the requirement of the crush material. If the material needs strong impact toughness, the high manganese blow bars are ideal selection. If we need high wear-resisting of blow bar, the chrome blow bar are our first choice. -

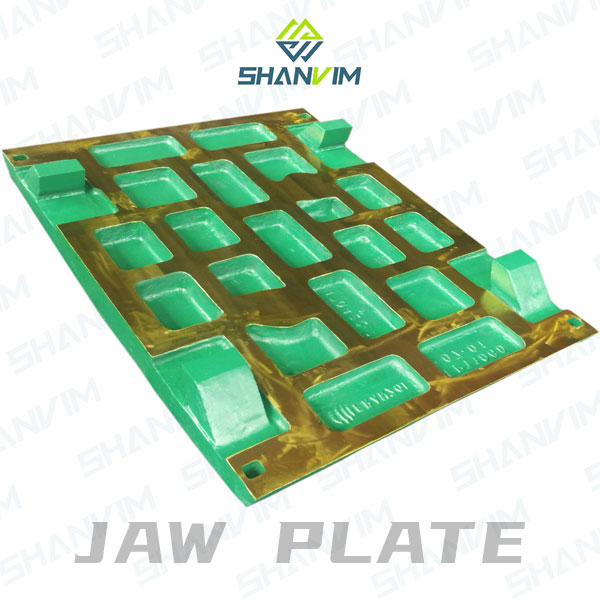

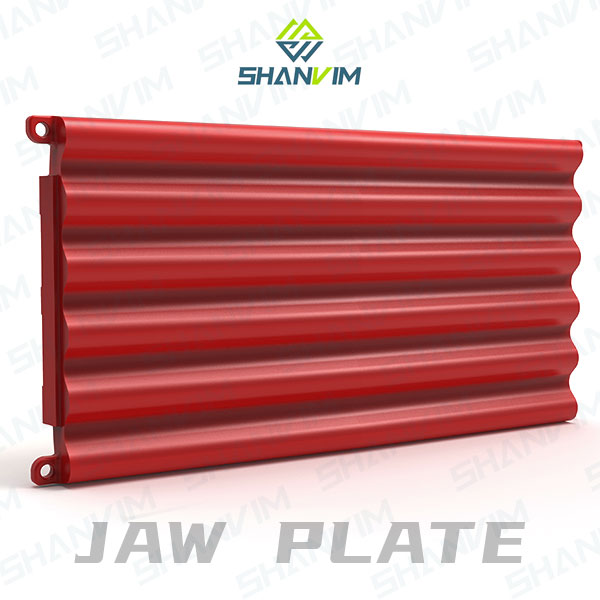

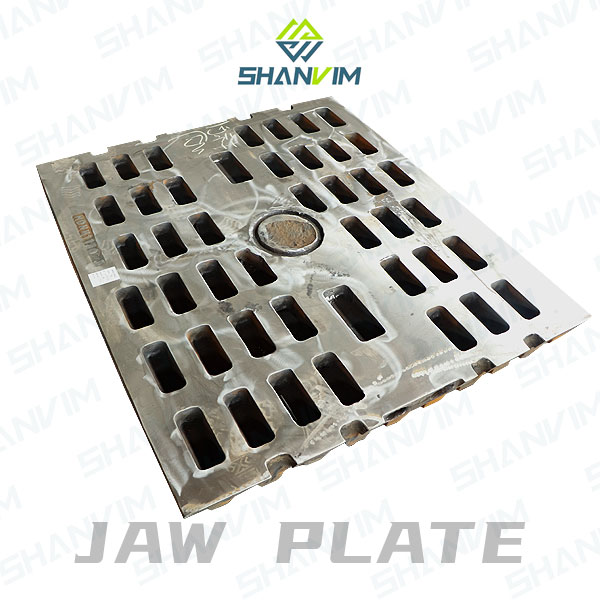

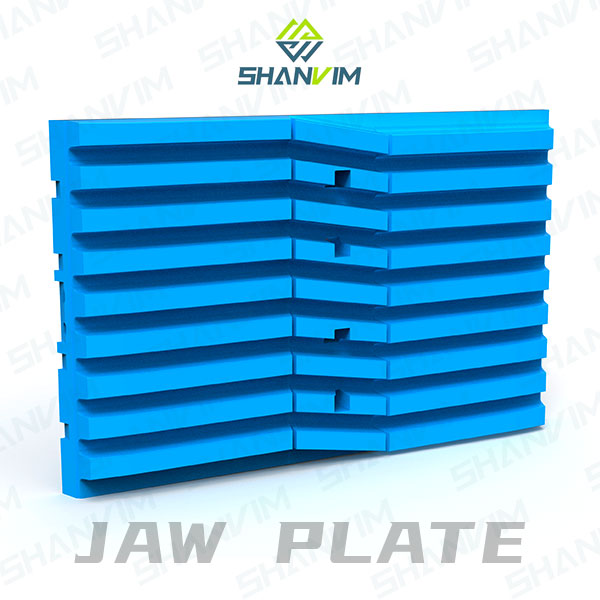

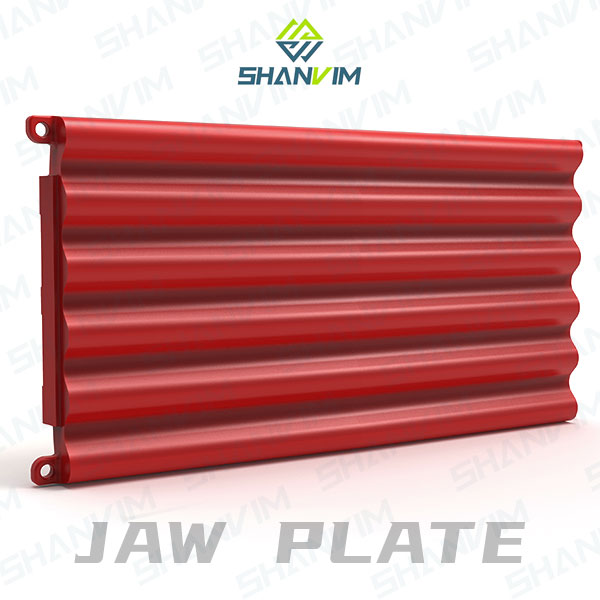

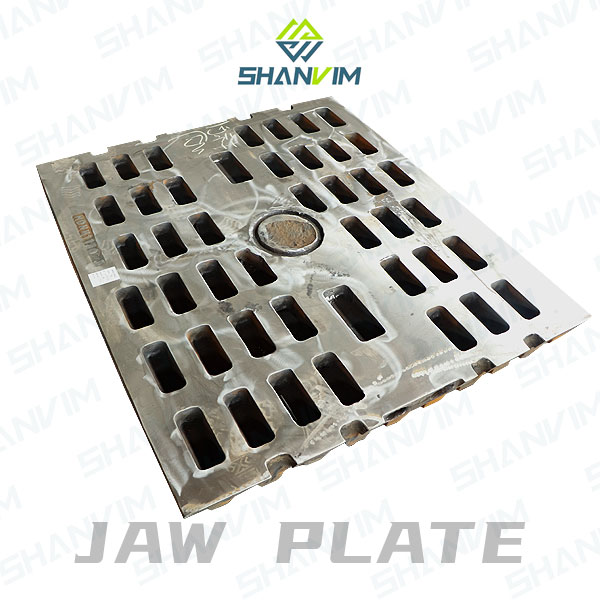

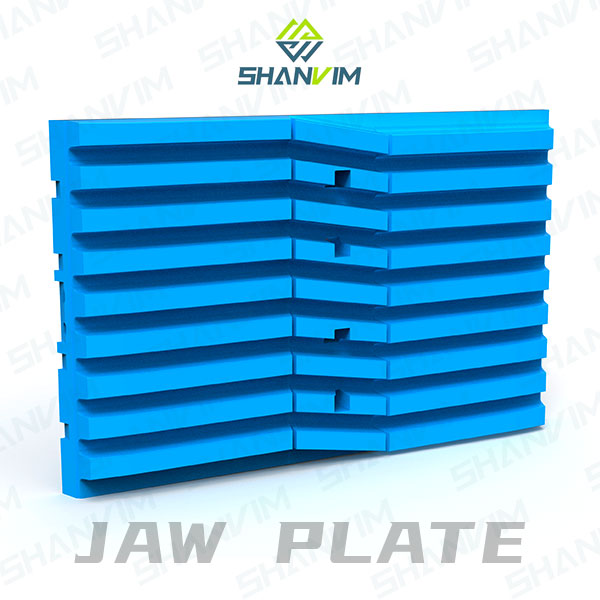

JAW PLATE-HIGH FEEICIENCY

SHANVIM replacement crusher jaws are engineered to last longer and crush more efficiently, while reducing wear and tear on the crusher.

The crusher jaws produce better quality rock more consistently than standard original equipment jaws, while reducing the need for re-screening and re-crushing. SHANVIM offers a full range of options for all popular jaw crushers, including various tooth designs, curves and alloys.

-

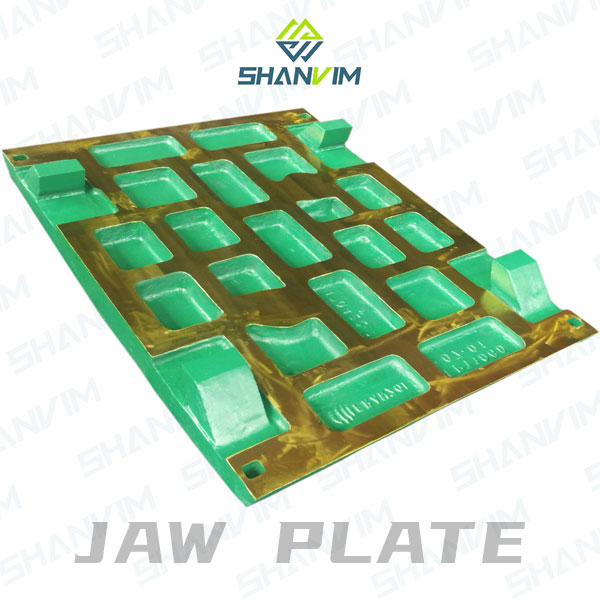

JAW CRUSHER PLATE-JAW LINER

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time.

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher is achieved when the movable jaw die presses the feed against the fixed jaw die. The rock remains in the jaw of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws. -

JAW PLATE-LONGEVITY

SHANVIM crusher jaws give you:

Machined surfaces for a consistent fit with less hassle and downtime.

Large selection of tooth and curve configurations for optimum performance in any application

Unsurpassed alloys for extended wear life and lower cost per ton.

As per the feedback from customers, the good performance of Jaw crusher spare parts in different working condition greatly decreased the time of examination & repair and the use-cost.

-

TIC INSERT JAW PLATE

The use of high-manganese steel or super-high manganese steel jaw plate as base material, in their work place composite inlaid carbide, the bi-metal composite wear parts wear surface has excellent wear resistance, non-wear surface with excellent plasticity And impact toughness. Installed by the user to use, consistent reflect the good results.

-

JAW PLATES FOR MINING INDUSTRY

Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials, widely used in mining, metallurgy, building materials, roads, railways, water conservancy and chemical industries. The highest crushing material is 320MPa. Jaw crusher parts can also be referred to as jaw crusher wear parts, is an important part of the jaw crusher; We can provide various types of jaw crusher wear parts, such as fixed jaw plate, movable jaw plate, toggle plate, liner plate, but also according to the drawings provided by customers to create different materials products.