-

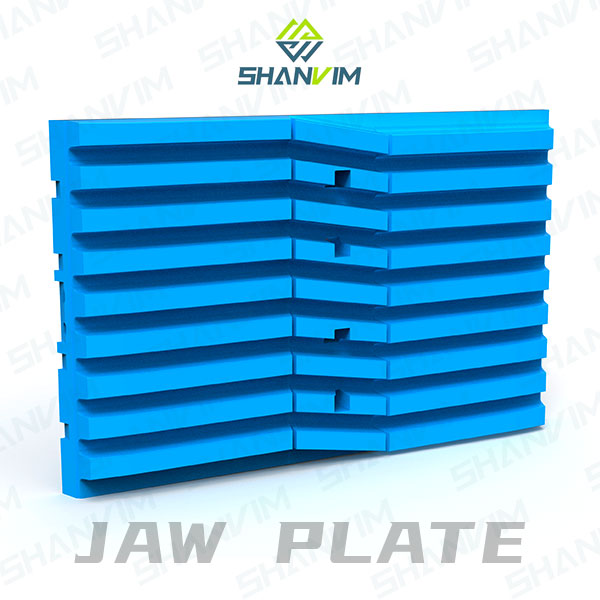

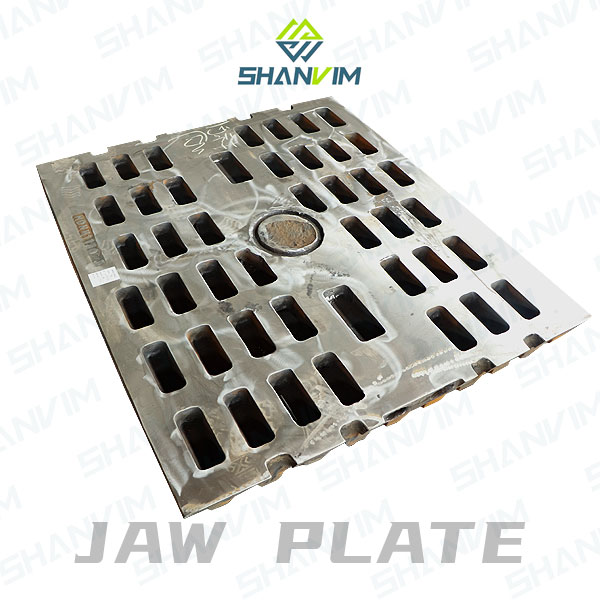

JAW PLATE-HIGH FEEICIENCY

SHANVIM replacement crusher jaws are engineered to last longer and crush more efficiently, while reducing wear and tear on the crusher.

The crusher jaws produce better quality rock more consistently than standard original equipment jaws, while reducing the need for re-screening and re-crushing. SHANVIM offers a full range of options for all popular jaw crushers, including various tooth designs, curves and alloys.

-

JAW PLATES FOR MINING INDUSTRY

Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials, widely used in mining, metallurgy, building materials, roads, railways, water conservancy and chemical industries. The highest crushing material is 320MPa. Jaw crusher parts can also be referred to as jaw crusher wear parts, is an important part of the jaw crusher; We can provide various types of jaw crusher wear parts, such as fixed jaw plate, movable jaw plate, toggle plate, liner plate, but also according to the drawings provided by customers to create different materials products. -

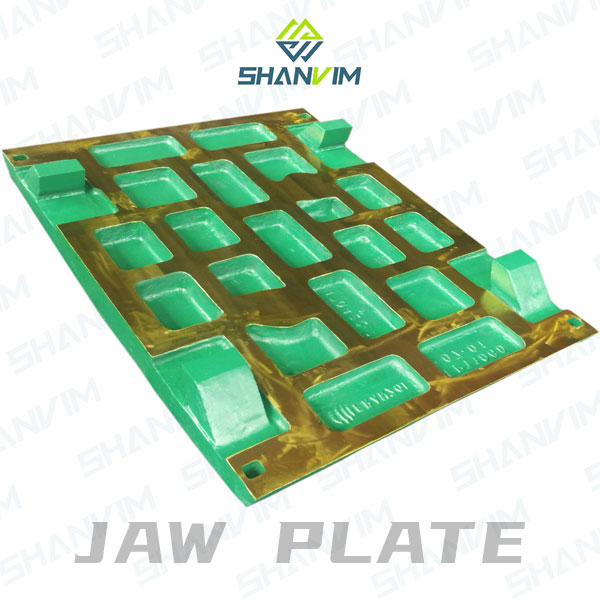

JAW CRUSHER PLATE-JAW LINER

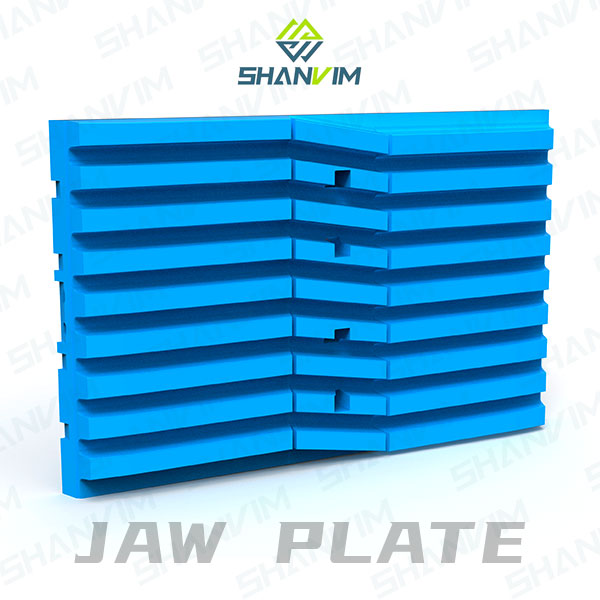

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time.

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher is achieved when the movable jaw die presses the feed against the fixed jaw die. The rock remains in the jaw of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws. -

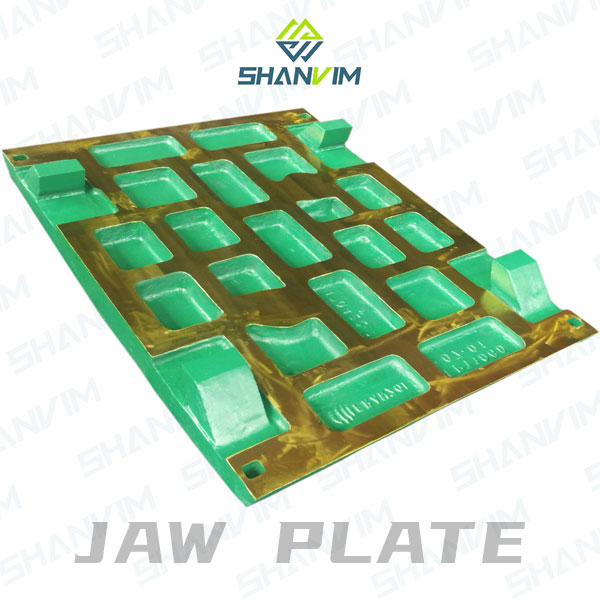

BI-METAL COMPOSITE JAW PLATE

In view of the working principle of jaw crusher and its practical application status, a double-liquid bimetallic composite casting jaw was developed. The working face is made of alloy steel with high wear resistance. The lining is made of cast steel with good impact toughness, Give full play to the characteristics of various materials. At the same time, the special pouring system and casting process ensure the uniform and complete interface of the composite material and optimize the service performance of the jaw plate.

-

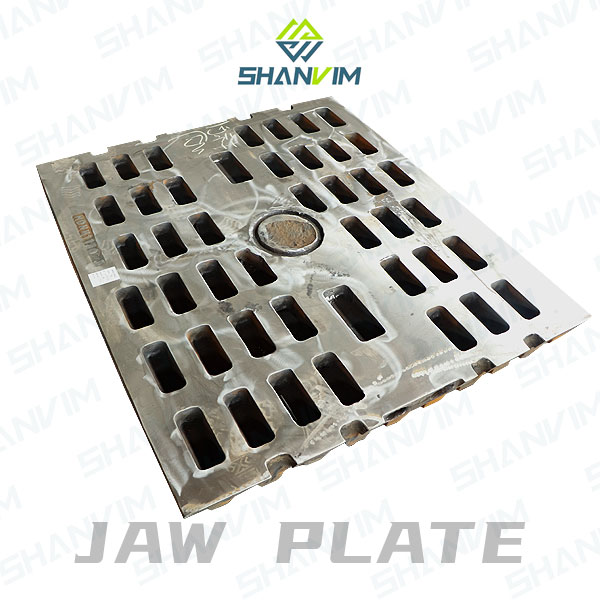

TIC INSERT JAW PLATE

The use of high-manganese steel or super-high manganese steel jaw plate as base material, in their work place composite inlaid carbide, the bi-metal composite wear parts wear surface has excellent wear resistance, non-wear surface with excellent plasticity And impact toughness. Installed by the user to use, consistent reflect the good results.

-

JAW PLATE-LONGEVITY

SHANVIM crusher jaws give you:

Machined surfaces for a consistent fit with less hassle and downtime.

Large selection of tooth and curve configurations for optimum performance in any application

Unsurpassed alloys for extended wear life and lower cost per ton.

As per the feedback from customers, the good performance of Jaw crusher spare parts in different working condition greatly decreased the time of examination & repair and the use-cost.

-

JAW PLATE FOR JAW CRUSHER

SHANVIM provides jaw liners made of manganese steel, which is suitable for various jaw crushers worldwide. Provide parts and technical support for the mining, aggregate, and recycling industry aftermarket. -

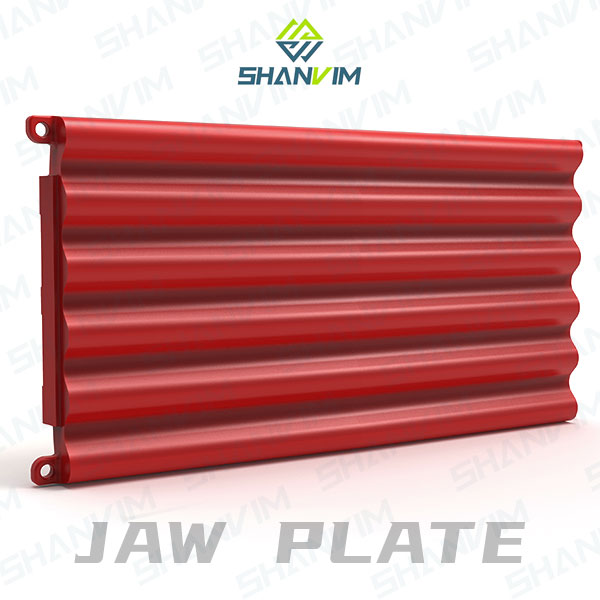

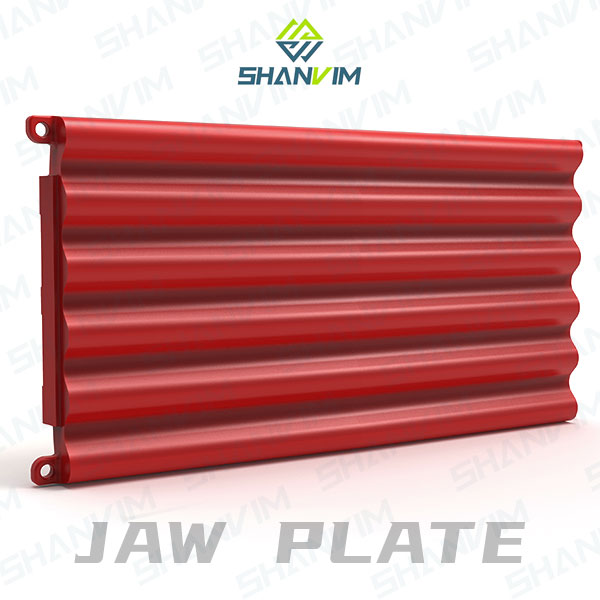

JAW PLATE MADE OF HIGH MANGANESE

High manganese steel is the traditional material of jaw plate , because it has good toughness and good deformation hardening ability. According to the element content, Mn13%,Mn13%,Cr2%,Mn18%,Mn18%Cr2%,Mn22%Cr2%.Or according to the special ingredients under working conditions, the jaw plate of the new micro alloy high manganese steel jaw crusher produced by Zhejiang Shanvim has fine workmanship, rigorous ingredients and in place heat treatment. -

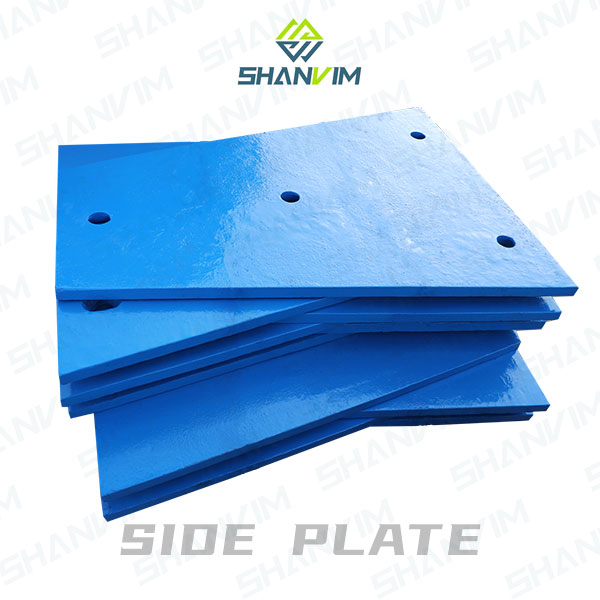

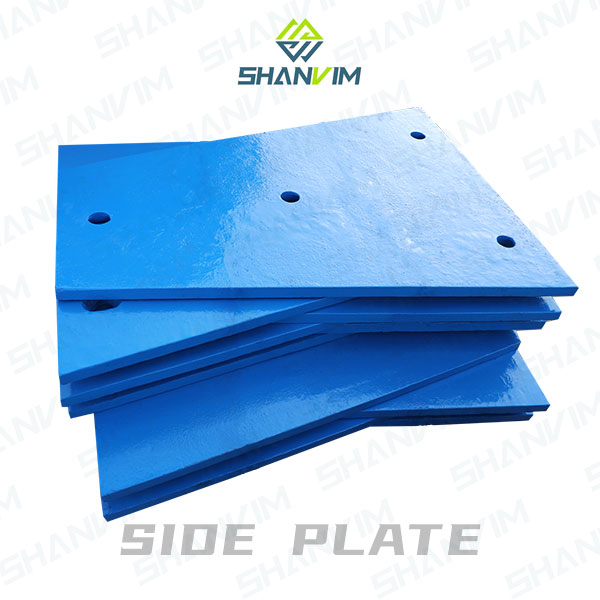

SIDE PLATES ARE ONE OF THE MAINLY REPLACEMENT PARTS OF JAW CRUSHER

Why Choose SHANVIM Side Plates

① Production quality testing: hardness testing, metallographic structure, machinery performance testing,ultrasonic inspection, high frequency infrared carbon and surface analysis etc.

② Competitive products: good quality with reasonable price.

③ Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

④ Professional: our factory has over 20 years working experience in casting and forging process and manufacture.

⑤ We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback. -

JAW CRUSHER WEAR PLATE-SIDE PLATE

SHANVIM– Your Trusted Jaw Crusher Parts Supplier

SHANVIM's jaw crusher spare parts and wear parts have been used and recognized by jaw crusher operators all over the world. We have reached agreements with several of the world’s most prestigious mining industry companies, and have been designated as the supplier of their jaw crusher parts. -

FIXED JAW PLATE FOR JAW CRUSHER

Crusher spare parts is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or manganese steel with special alloy and heat-treatment process. Jaw crusher spare parts has a working life of 10%-15% longer than those made of traditional manganese steel.