-

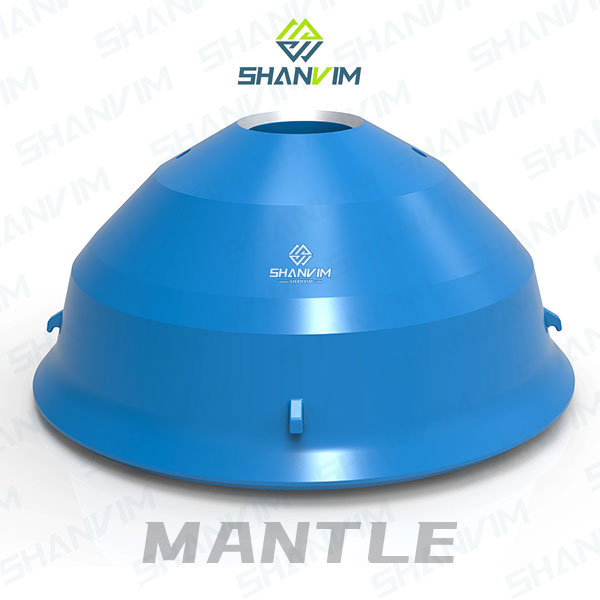

I-MANGANESE ESENTELE EPHAKAMILEYO ESEBENZAYO KWI BOWL LIER

Umxholo weShanvim Concave kunye ne-Mantle: MN13CR2, MN18CR2, i-MN28CR2, i-BRE 40, i-BRE 40, GX i-48 MN20 GR D, SABS 407 Uhlobo 4, ASTM A128 Gr E, SABS 407 Uhlobo 5

Ngenkqubo ekhethekileyo yokunyanga ubushushu kunye Nokwakheka kweekhemikhali ezikhethekileyo, iSHANVIM cone mantle & nesitya sesitya sinobomi benkonzo obungama-30% ubude kunobo bentsimbi yesiko yemanganese! -

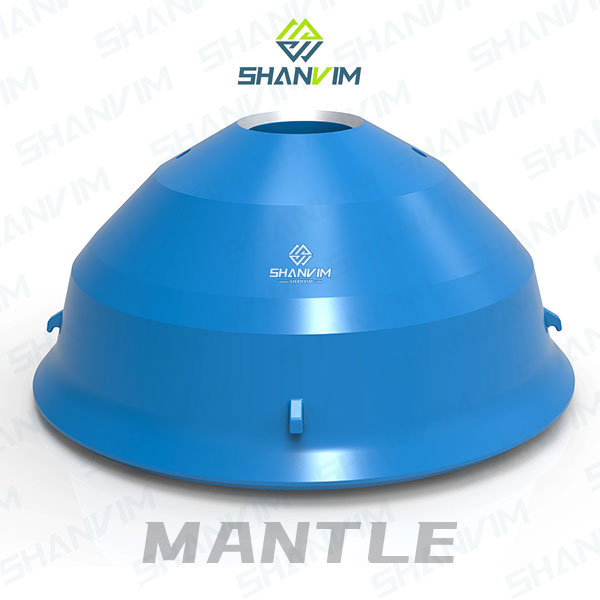

I-MANTLE-CONE CRUSHER PARTS FOR THEYING

Xa kufikwa kwiindawo zokutyumza iikhowuni endaweni, i-SHANVIM ibiyityumza intengiso amashumi eminyaka.Ukuba ufuna uxolo lwengqondo oluza ne-ISO 9001-eqinisekisiweyo, eqinisekisiweyo ngokupheleleyo kunye neendawo eziqinisekisiweyo endaweni yesityumli sakho sekhowuni, uphendlo lwakho luphela ngo-SHANVIM MACHINERY-Izahlulo zakho zokuTshintshwa kweCone Crusher SuperStore.I-SHANVIM yenza amacandelo okutshintshwa kwezitshizi zohlobo ezininzi kwihlabathi liphela. -

I-CHROMIUM EPHAKAMILEYO YE-METALI YE-CERAMIC IMIBHALO YOKUVUTHELA

IiNdibaniselwano zeMetal Matrix (MMC) iiBha zokuvuthela zeCeramic ezaziwa ngokuba ziiBar zeCearmic Blow, ziquka:

I-Chrome ye-Iron Matrix eneeMibhalo zeCeramic zokuVuthela;

I-Martensitic Alloy Steel Matrix eneCeramic Composites Blow Bars;

Ibha yeCeramic Blow yenye yezona ndawo ziqhelekileyo zokunxiba iinxalenye zokunxiba isityumzi.Idibanisa ukuchasana okuphezulu kwe-matrix yentsimbi kunye neekeramics ezinzima kakhulu.

I-porous preforms eyenziwe ngamaqhekeza e-ceramic iveliswa kwinkqubo.Ubunzima besinyithi obutyhidiweyo bungena kwinethiwekhi ye-ceramic eneporous. -

MANTLE-TIC FAKA intsimbi yentsimbi

Ukusetyenziswa kwexabiso eliphantsi eliphezulu-manganese intsimbi okanye super-high-high manganese intsimbi kwiindawo ezinkulu ukunxitywa kwemathiriyeli yesiseko, amacandelo ahlanganisiweyo kumsebenzi wabo carbide inlaid, i-bimetal composite ukunxiba iindawo zokunxiba umphezulu unokumelana okugqwesileyo, ukunganxibi. Imaski ineplastiki egqwesileyo kunye nokuqina kwempembelelo, ukunciphisa ukunxiba kwe-matrix yentsimbi ephezulu ye-manganese, ukuze i-mantle kunye ne-concave yandise kakhulu ubomi benkonzo. -

I-BOWL LINER-MINING EQUIPMENT PARTS

Izityumzi zecone zisetyenziswa kakhulu kwimigodi kunye nakwimizi-mveliso edityanisiweyo ukunciphisa ubungakanani bamatye aqhushumbayo ngokucinezela imathiriyeli phakathi kwengubo yokutyumza ikhowuni kunye nesitya sesitya.

I-mantle igqume intloko ye-cone ukuyikhusela ekugugile, sinokuyibona njengento yokunxiba yedini ehlala entloko ye-cone.

Kwaye isitya sesitya esikwabizwa ngokuba yi-cone crusher concave, sisinxibo sedini esinxitywayo esiseta ngaphakathi kwesakhelo esingaphezulu sokukhusela izincedisi eziphezulu zecone crusher.

I-SHANVIM® i-cone crusher mantle kunye ne-bowl liner zenzelwe ukuphucula ukusebenza kakuhle kunye nokunciphisa iindleko ngokwandisa ubomi bokunxiba kunye nokunciphisa ixesha lokuphumla.

-

MANTLE-GOOD EMVA-UKUTHENGISWA KWENKONZO

Isininzi se-13%-22%Mn yeprimiyamu yomgangatho we-Mn Liners kwi-SHANVIM ukuze zilungele izityumzi.Iingcali ze-Aftermarket zibonelela ngezisombululo zokutyumza kunye nezimbiwa kwimigodi, kumashishini adityanisiweyo kunye namashishini okurisayikilisha!

I-SHANVIM ibonelela ngomnikelo opheleleyo, kuzo zombini iindawo ezisemgangathweni kunye nezobunjineli zokuodola, ukuqinisekisa ukuba ubukho kunye nenkxaso efunekayo.Sinikezela ngeendlela eziguquguqukayo zokukhusela iinxalenye ngexesha elinye, njengenkonzo yesitshixo sokujika, okanye naphi na phakathi. -

UMANGANESE OPHAKAMILEYO WOBHOVA BAR

Ibha yokuvuthela yeyona ndawo iphambili yesixhobo sokutyumza.Kukho ibha yokuvuthela yemanganese ephezulu, ibha yokuvuthela ye-chrome ephezulu.Izinto eziphathekayo zixhomekeke kwimfuno yezinto eziphathekayo.Ukuba imathiriyeli ifuna ukuqina kwempembelelo eyomeleleyo, imivalo yokuvuthela yemanganese ephezulu ilukhetho olufanelekileyo.Ukuba sifuna ukuxhathisa okuphezulu kwebha yokuvuthela, ibha yokuvuthela ye-chrome lukhetho lwethu lokuqala. -

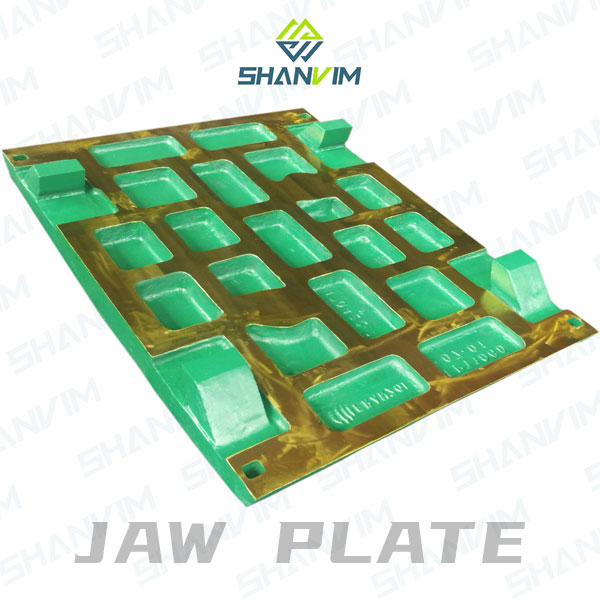

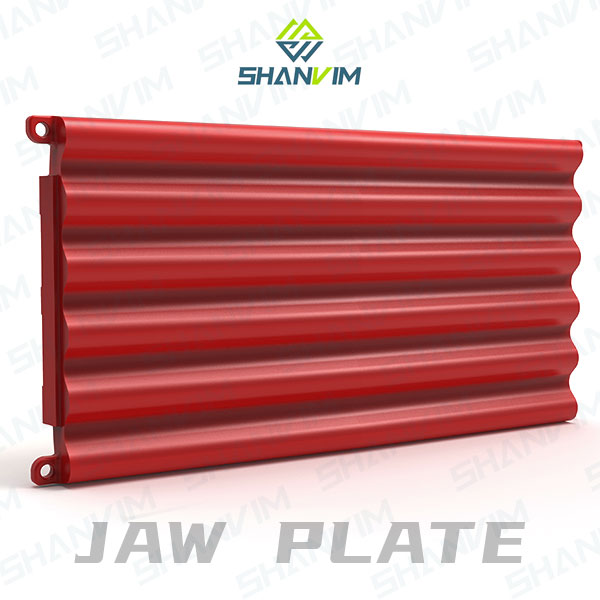

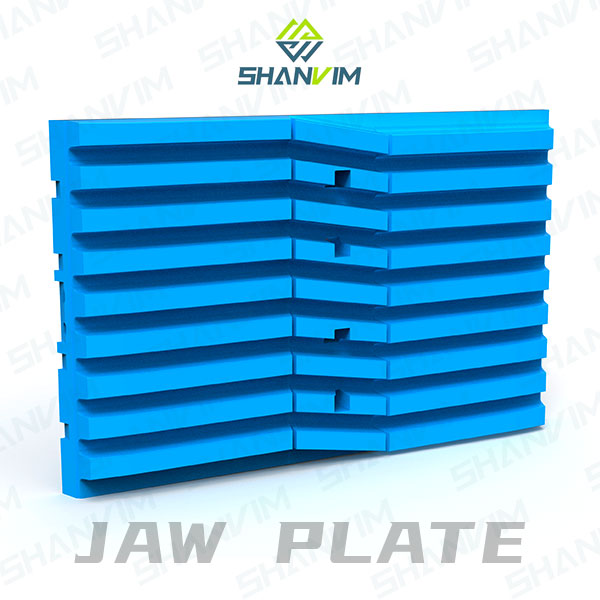

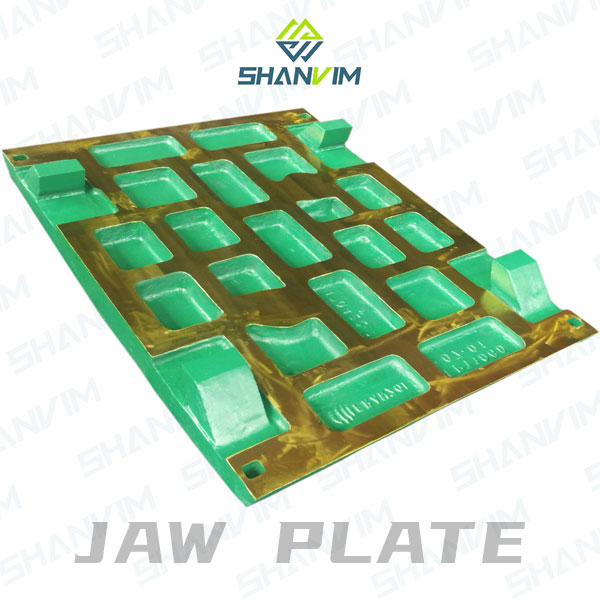

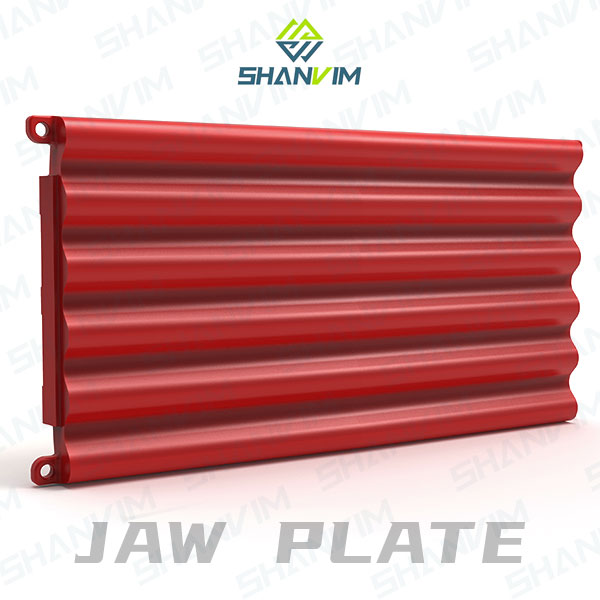

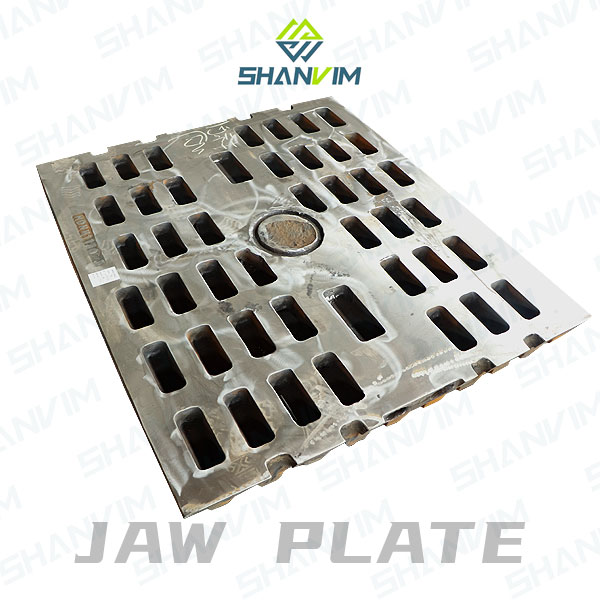

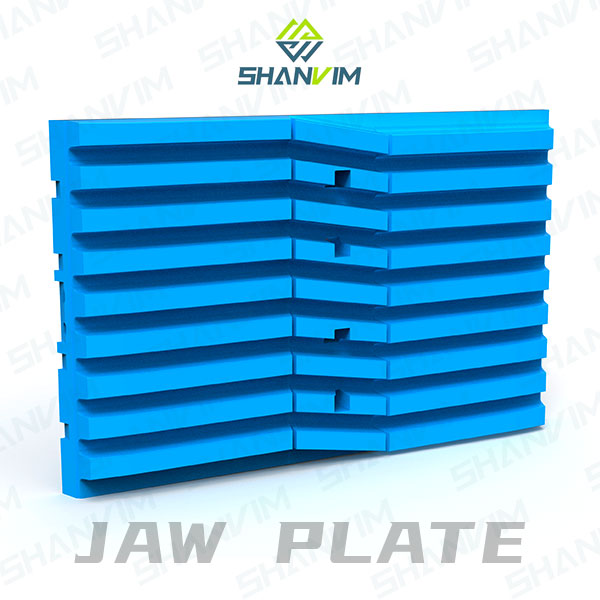

IPLATE YOMHLATHI-EMPHEZULU

I-SHANVIM yokutshintsha imihlathi ye-crusher yenziwe ukuba ihlale ixesha elide kwaye ityumke ngokufanelekileyo, ngelixa inciphisa ukuguga kunye nokukrazula kwisityuli.

Imihlathi yokutyumza ivelisa umgangatho ophucukileyo wamatye ngokuthe gqolo kunemihlathi yesixhobo soqobo esisemgangathweni, ngelixa kuncitshiswa imfuno yokuhlolwa kwakhona kunye nokutyumza kwakhona.I-SHANVIM ibonelela ngoluhlu olupheleleyo lokhetho kuzo zonke izityumli zemihlathi ezidumileyo, kubandakanywa uyilo lwamazinyo olwahlukeneyo, iigophe kunye nealloys.

-

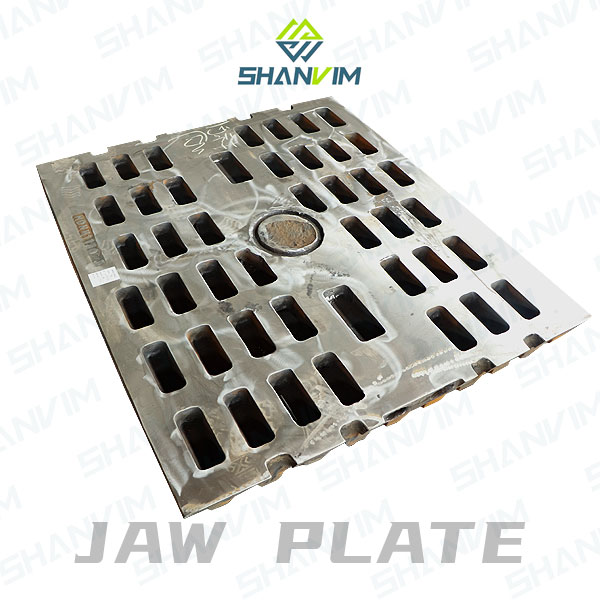

UMHLATHI CRUSHER PLATE-JAW LIER

Iipleyiti zemihlathi okanye i-Jaw Dies zezona nxalenye zokunxiba ezihlala zitshintshwa zesityuli somhlathi, ngoko umgangatho wokufa kwemihlathi yenye yezona zinto zibalulekileyo ezimisela ukusebenza kakuhle kunye nexesha lokusebenza.

Iseti yeepleyiti zemihlathi zenziwe ngezinto ezinokususwa (umhlathi ojingi) kunye nepleyiti yomhlathi esisigxina (umhlathi omileyo).Ukucinezelwa kwezinto ezityumzwayo kwisityuli somhlathi kufezekiswa xa ifa lomhlathi elishukumayo licinezela umxhesho wokufa kwemihlathi esisigxina.Ilitye lihlala emhlathini womatshini wokutyumza de libe lincinci ngokwaneleyo ukudlula kwi-gap ukuya emazantsi emihlathi. -

IPLATE YOMHLATHI-UBUDE

SHANVIM imihlathi yokutyumza ikunika:

Imiphezulu eyenziwe ngoomatshini ukuze ilingane kunye nokuphazamiseka okuncinci kunye nexesha lokuphumla.

Ukhetho olukhulu lwezinyo kunye nolungelelwaniso lwegophe ukwenzela ukusebenza ngokugqibeleleyo kuso nasiphi na isicelo

Iialloyi ezingagqithwanga zobomi obude bokunxiba kunye neendleko eziphantsi ngetoni nganye.

Ngokwengxelo evela kubathengi, ukusebenza kakuhle kwamalungu e-Jaw crusher akwimo yokusebenza eyohlukeneyo kulihlise kakhulu ixesha loviwo kunye nokulungiswa kunye neendleko zokusebenzisa.

-

I-TIC FAKA Ipleyiti yomhlathi

Ukusetyenziswa kwentsimbi ephezulu-manganese okanye ipleyiti yomhlathi ephezulu yemanganese njengesiseko semathiriyeli, kwindawo yabo yokusebenza idityanisiwe ye-carbide ehlanganisiweyo, i-bi-metal composite edityanisiweyo yamalungu okunxiba umphezulu inokumelana nokunxiba okugqwesileyo, indawo enganxibanga eneplastiki egqwesileyo kunye nefuthe. ubunzima.Ifakwe ngumsebenzisi ukuba isetyenziswe, ibonakalisa iziphumo ezilungileyo.

-

IIpleyiti zemihlathi YEMIGODI INDUSTRI

Isityumsi somhlathi sisetyenziswa ikakhulu ukutyumza ubungakanani obuphakathi bentsimbi ekrwada kunye nemathiriyeli eninzi, esetyenziswa kakhulu kwimigodi, isinyithi, izixhobo zokwakha, iindlela, oololiwe, ukongiwa kwamanzi kunye namashishini amachiza.Eyona nto iphezulu yokutyumza yi-320MPa.Iindawo zokutyumza imihlathi nazo zingabhekiswa njengeendawo zokunxiba zemihlathi, yinxalenye ebalulekileyo yesityuli somhlathi;Sinokubonelela ngeentlobo ezahlukeneyo zeendawo zokunxiba ze-jaw crusher, ezifana nepleyiti yomhlathi esisigxina, ipleyiti eshukumayo yomhlathi, ipleyiti yokuguqula, ipleyiti ye-liner, kodwa nangokwemizobo ebonelelwa ngabathengi ukwenza iimveliso ezahlukeneyo zezinto.