PRODUCTS

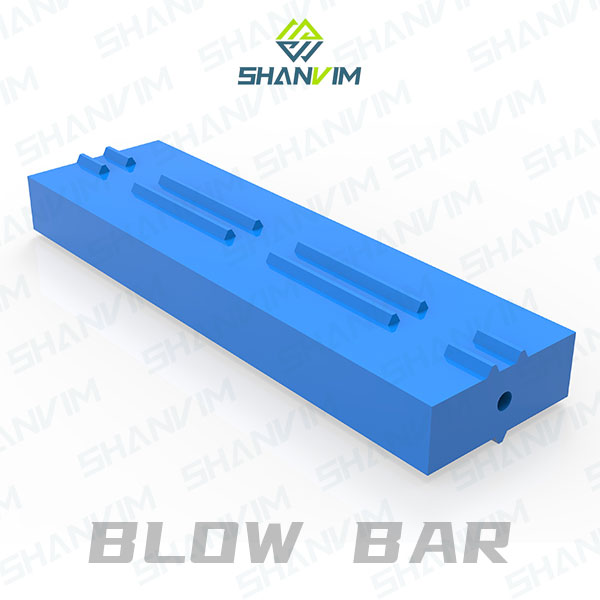

HIGH MANGANESE BLOW BAR

Description

Blow bars are thick slabs of metal, typically some mixture of chrome, that are forged for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etc.

Blow bar is a critical part during the crushing process with horizontal shaft impactor. Materials of the blow bars are usually selected according to the function of the impact crusher.

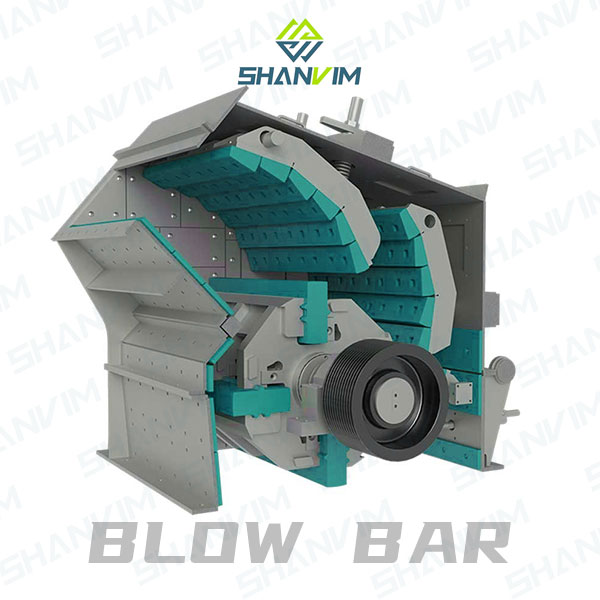

When set in the horizontal impact crushers, blow bars are inserted into the rotor and rotated at high speeds, making the whole rotor assembly spins repeatedly striking the material. During this process, the blow bar fractures the materials until it meets the appropriate size to fall out through the impact crusher chamber.

Genuine Alternative Spare Parts - Impact Crusher Blow Bars Made By SHANVIM

SHANVIM® offers different designs and manufactures various solutions of blow bar for an extensive range of OEM horizontal impact crusher brands including: Hazemag, Mesto, Kleemann, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Eagle, Tesab, Finlay and others. SHANVIM® "Genuine Alternative" blow bars are designed to extend wear life, provide a perfect interchangeable fitting for your impactor, and increase production rates while decreasing costs-per-ton.

SHANVIM® Alternative Blow Bars Available For Below Models Collapse

Both stationary and movable jaw die could be flat surfaced or corrugated. In general, jaw plates are made of high manganese steel which is the dominant wear material. High manganese steel is also known as Hadfield manganese steel, a steel whose manganese content is very high and which possesses austenitic properties. Such plates are not only extremely tough but are also quite ductile and work-harden with use.

We offer jaw plates in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%. Check below table of our high manganese jaw die properties:

Metallurgy of the Blow Bars

SHANVIM crusher blow bars are available in a variety of metallurgies to accomodate your unique crushing needs. The range of metallurgies includes Manganese, Low Chrome, Medium Chrome, High Chrome, Martensitic and Composite Ceramic.

As shown in the figure, an increase in the steel's wear resistance (hardness) is usually accompanied by a reduction in toughness (impact resistance) of the material.

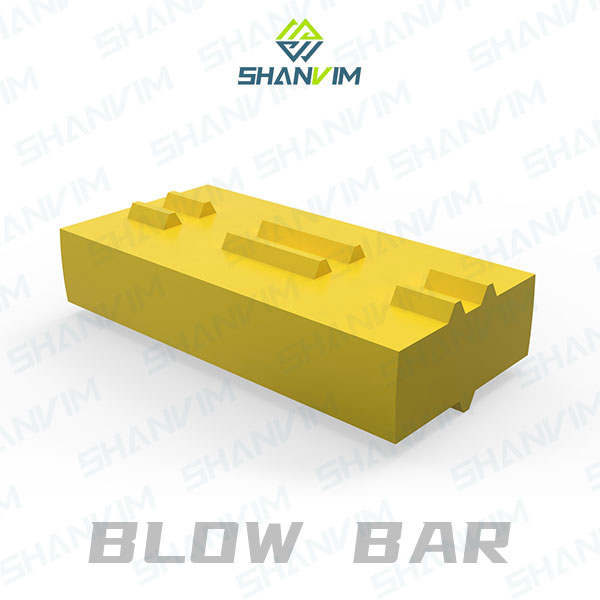

MANGANESE STEEL

The wear resistance of manganese steel with austenitic structure is attributable to the phenmenon of work hardening. The impact and pressure load results in a hardening of the austenitic structure on the surface. The initial hardness of manganese steel is approx. 20 HRC. The impact strength is approx. 250J/cm².

After the work hardening, the initial hardness can thereby reach upto approx. 50 HRC. The deeper-set, not yet hardened layers thereby provide for the great toughness of this steel. The depth and hardness of the work-hardened surfaces depend on the application and type of manganese steel.

Manganese steel has a long history. Today, this steel is used mostly for crusher jaws, crushing cones and crushing shells (mantles & bowl liners). In the impact crusher, it is only recommended to use manganese blow bars when crushing less abrasive and very large feed material (e.g. limestone).

CHROME STEEL

With chrome steel, the carbon is chemically bonded in the form of chromium carbide. The wear resistance of chrome steel is based on these hard carbides of the hard matrix, whereby the movement is hindered by offsets, which provides for a high degree of strength but at the same time less toughness.

To prevent the material from becoming brittle, the blow bars must be heat-treated. It must thereby be observed that the temperature and annealing time parameters are exactly adhered to. Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm².

To prevent breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material.

SHANVIM Chorme Blow Bars Elements

|

High Chrome Casting Material Chemical Composition |

|||||||||

|

Code Elem |

Cr |

C |

Na |

Cu |

Mn |

Si |

Na |

P |

HRC |

|

KmTBCr4Mo |

3.5-4.5 |

2.5-3.5 |

/ |

/ |

0.5-1.0 |

0.5-1.0 |

/ |

≤0.15 |

≥55 |

|

KmTBCr9Ni5Si2 |

8.0-1.0 |

2.5-3.6 |

4.5-6.5 |

4.5-6.5 |

0.3-0.8 |

1.5-2.2 |

4.5-6.5 |

/ |

≥58 |

|

KmTBCr15Mo |

13-18 |

2.8-3.5 |

0-1.0 |

0-1.0 |

0.5-1.0 |

≤1.0 |

0-1.0 |

≤0.16 |

≥58 |

|

KmTBCr20Mo |

18-23 |

2.0-3.3 |

≤2.5 |

≤1.2 |

≤2.0 |

≤1.2 |

≤2.5 |

≤0.16 |

≥60 |

|

KmTBCr26 |

23-30 |

2.3-3.3 |

≤2.5 |

≤2.0 |

≤1.0 |

≤1.2 |

≤2.5 |

≤0.16 |

≥60 |

MARTENSITIC STEEL

Martensite is a completely carbon-saturated type of iron that is made by quick cooling-off. It is only in the subsequent heat treatment that carbon is removed from the martensite, which improves the strength and wear properties. The hardness of this steel ranges between 44 to 57 HRC and the impact strength between 100 and 300 J/cm².

Thus, with regard to hardness and toughness, martensitic steels lie between manganese steel and chrome steel. They are used if the impact load is too little to harden the manganese steel, and/ or good wear resistance is required along with good impact stress resistance.

METAL MATRIX WITH CERAMIC COMPOSITES

Metal Matrix Composites, combine the high resistance of the metal matrix with extremely hard ceramics. Porous preforms made of ceramic particles are produced in the process. The metallic molten mass penetrates into the porous ceramic network. The experience and knowledge are particular to the casting process in which two different materials - steel with a thichness of 7.85 g/cm³ and ceramic with a thickness of 1-3 g/cm³ - are combined and there is a thorought infiltration.

This combination makes the blow bars especially wear-resistance but at the same time very impact-resistant. With blow bars made of composites from the field of ceramics, a service life that is three to five times as long as that of martensitic steel can be achieved.