PRODUCTS

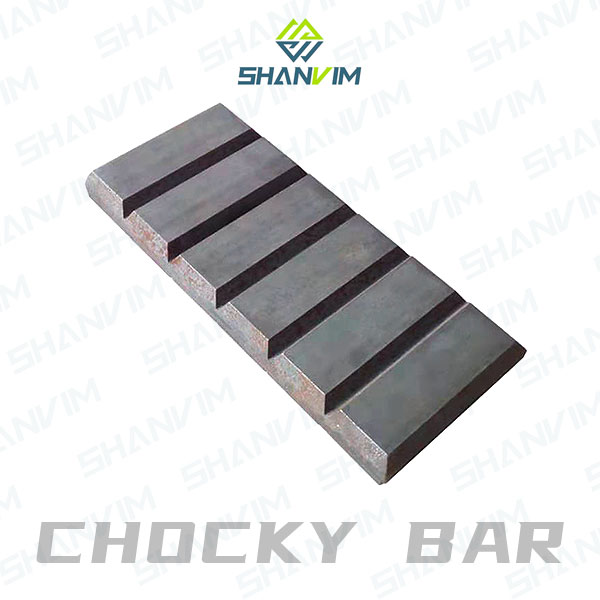

CHOCKY BARS WITH METAL CERAMIC

This practice is suitable for Chocky bars only.

Note: For severe curves with a radius of less than 305mm, or inside curves, it is advisable to notch the mild steel

backing plate opposite the “V” to assist forming. (Figure A)

The Chocky bar may crack during bending. This is normal.

1. Clean the surface to which chocky bar will be welded.

2. Tack weld one end of the chocky bar(as per the welding procedure) in at least 3 places by 15mm minimum

length per weld(Figure 1)

3. Outside Curves: Hammer down unwelded end of bar with a soft face hammer to bend bar to match mating

radius. (Figure 2)

4. Inside curves: Starting the center strike bar with a soft face hammer to bend bar to match mating radius.

(Figure 3)

5. Cutting Details: High pressure abrasive water jet cutting is the preferred cutting method. Thermal cutting

using an oxyacetylene torch, arc-air or plasma is NOT recommended due to high localized heat input and high

risk of cracking, cutting by abrasive disc is an accepted practice.