LIHLAHISO

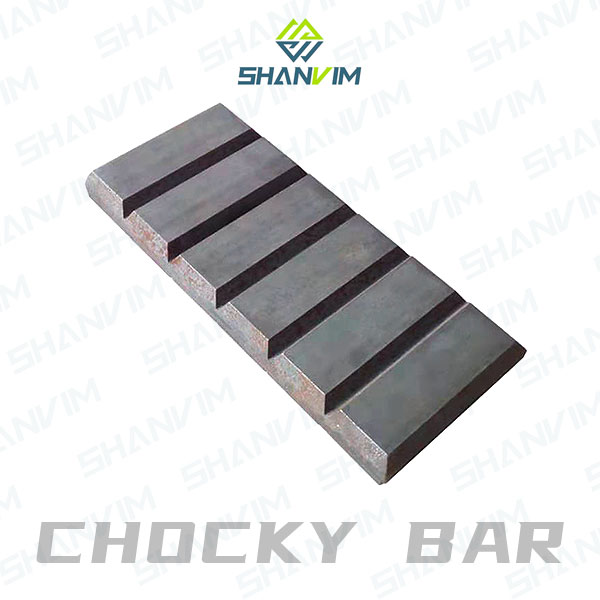

CHOCKY BARS LE TŠEPANG CERAMIC

Mokhoa ona o loketse li-Chocky bar feela.

Tlhokomeliso: Bakeng sa li-curve tse matla tse nang le radius e ka tlase ho 305mm, kapa li-curve tse ka hare, ho bohlokoa ho nottch tšepe e bonolo.

poleiti e tshehetsang e shebaneng le “V” ho thusa ho bopa.(Setšoantšo A)

Chocky bar e ka 'na ea peperana nakong ea ho kobeha.Sena se tloaelehile.

1. Hloekisa bokaholimo boo chocky bar e tla chesetsoa ho eona.

2. Tobetsa ntlha e le 'ngoe ea chocky bar (ho ea ka mokhoa oa ho cheselletsa) bonyane libakeng tse 3 ka bonyane ba 15mm.

bolelele ka weld (setšoantšo sa 1)

3. Li-Curves tse ka Ntle: Hatela fatše pheletsong e sa lokisoang ea hamore ka hamore e bonolo ea sefahleho ho kobeha bar ho tsamaisana le ho nyalana.

radius.(Setšoantšo sa 2)

4. Li-curve tse ka hare: Ho qala setsi sa ho otla se bohareng ka hamore e bonolo ea sefahleho ho koba bar ho tsamaisana le radius ea ho nyalana.

(Setšoantšo sa 3)

5. Lintlha tsa ho Seha: Khatello e phahameng ea abrasive water jet cutting ke mokhoa o khethiloeng oa ho itšeha.Thermal cutting

Ho sebelisa toche ea oxyacetylene, arc-air kapa plasma HA HO khothaletsoe ka lebaka la ho kenya mocheso o phahameng oa lehae le holimo.

kotsi ea ho petsoha, ho itšeha ka abrasive disc ke mokhoa o amohelehang.