News

-

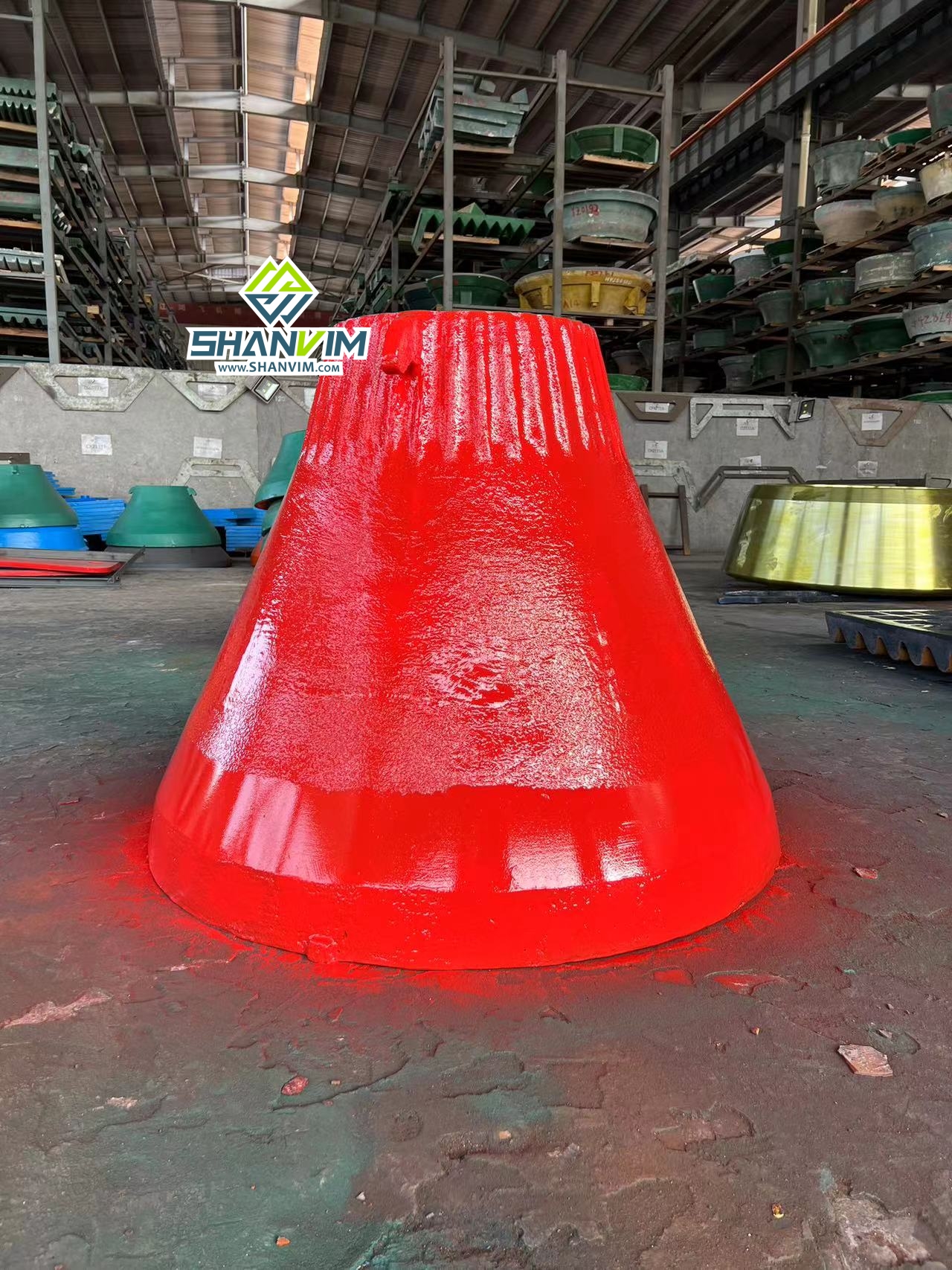

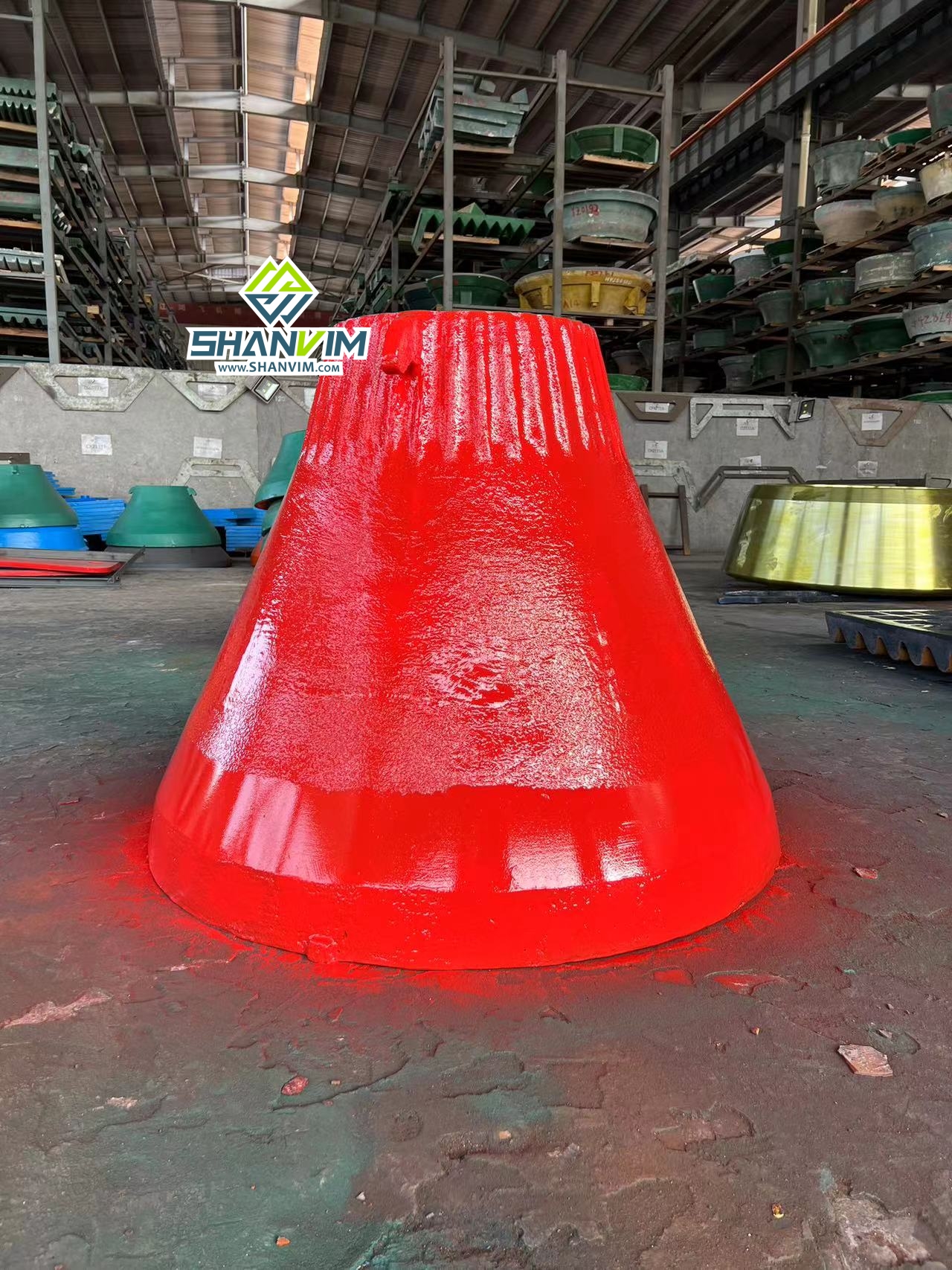

Highly wear-resistant liner plate – Shanvim casting

Shanvim produces high wear-resistant liners, which are new wear-resistant products developed by absorbing domestic and foreign advanced technology, among which high chromium alloy liners are a new generation of crusher liners developed by combining with the specific industrial and mining conditio...Read more -

How to choose a mining crusher suitable for you?

Mining crushers are widely used in mining, smelting, building materials, highways, railways, water conservancy, chemical industry and other sectors. It has the characteristics of large crushing ratio, simple structure, simple maintenance, economy and durability. Commonly used mining crushers incl...Read more -

What material is the hammer of a crusher generally made of?

What material is the hammer of a crusher generally made of? What material is inside the hammer? The material inside the broken hammer is high chromium alloy. High chromium alloy is a wear-resistant material with excellent anti-wear properties, but its toughness is low and brittle fracture occurs....Read more -

Shanvim introduces machine tool base to you

The base of the machine tool is made of HT300 material, resin sand casting process, and all scrap steel plus carburizing agent induction furnace smelting process to effectively ensure the strength, hardness, and stiffness requirements of the machine tool. CNC machine tools are composed of a base,...Read more -

How to solve the problem of high moisture content of materials that easily adheres to the cone crusher?

Cone crusher is a common crushing equipment widely used in mining, construction, metallurgy, chemical industry and other industries. However, the high moisture content of the material tends to adhere to the cone crusher, resulting in unstable equipment operation and reduced production efficiency....Read more -

Properly configure crushing production line equipment to achieve efficient production capacity

With the acceleration of industrialization, iron ore, as one of the important raw materials in the steel industry, plays a vital role in modern society. In order to meet the growing demand, it is particularly important to build an efficient fixed iron ore crushing production line with an output o...Read more -

Steel castings are better than iron castings. What are the characteristics of its casting process?

What manufacturers hear most is why your steel castings are not made of iron castings? Or whether do you make cast iron parts?Many people have questions about the difference between steel castings and iron castings. Why do large foundries prefer to cast large steel castings? That’s because...Read more -

What is the difference between gyratory crusher and jaw crusher?

Gyratory crusher and jaw crusher are both equipment used for crushing sand and gravel aggregates. They are similar in function. The two shapes and sizes are quite different. The gyratory crusher has a larger processing capacity. So the two have What are the more specific differences? Advantages ...Read more -

Shanvim tell you about casting defects caused by bad paint

When steel casting manufacturers cast castings, they often cause defects in the castings due to coating quality problems. Many people are confused that coating is just a small step. How can this happen? In fact, there are no big or small steps in casting. Mistakes in any even inconspicuous step w...Read more -

The quality of the hammer plays an important role in the operation of the counterbalance hammer crusher

The abnormal vibration of the crusher is not normal, so it needs to be dealt with as soon as possible. The earlier the treatment, the smaller the impact on the equipment and the smaller the impact on production. Summarized below are the following methods our engineers provide for such failures. ...Read more -

How to choose single-cylinder and multi-cylinder cone crusher?

Cone crusher is a medium and fine crushing equipment that is widely used in various major industries, such as metallurgy, construction, road construction, mining, quarries and other fields. The cone crusher has a variety of cavity types to choose from, and the discharge port is easy to adjust. Th...Read more -

On December 13, 2023, the inlaid alloy jaw plate delivery site

On the bright morning of December 13, 2023, Shanvim Industry was very busy, because countless crushing equipment was about to be shipped. The jaw plate of the CJ412 jaw crusher is the main ore processing machine of our factory. This month, 20 tons of the same jaw plate have left the factory, whic...Read more