PRODUCTS

Sand Making Machine Factories – MANTLE-GOOD AFTER-SALES SERVICE – Jinhua

Sand Making Machine Factories – MANTLE-GOOD AFTER-SALES SERVICE – Jinhua Detail:

Description

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.

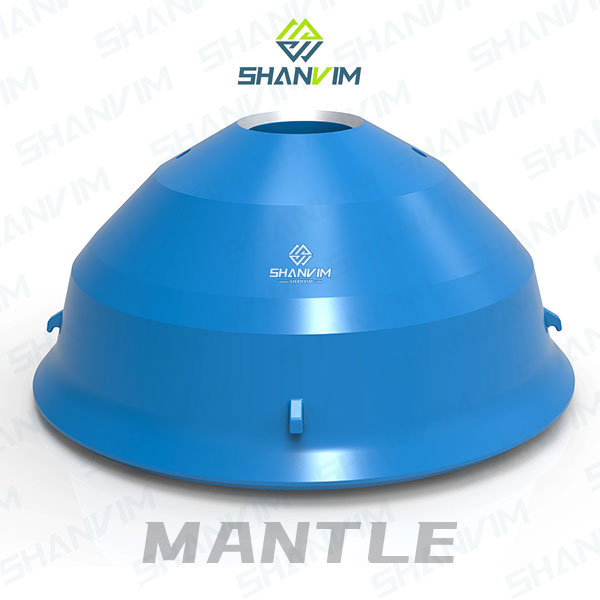

The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

SHANVIM® cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

SHANVIM® manufactures stocks and supplies “Genuine Alternative” cone crusher parts of an extensive range of OEM including but not limited to: Metso®, Sandvik®, Extec®, Telsmith®, Terex®, Powerscreen®, Flsmidth® and others.

Notice: The following table does not include all the alternative genuine accessories that we can produce. If you need accessories from other brands, or know the OEM serial number of the mantle or bowl liner that you are looking to replace, or can provide the drawing of the parts that you need to customize, please feel free to contact us by email or call.

The mantle and concave are often made of austenitic manganese steel, a material well known for its work hardening capability.

We offer cone crusher mantles and bowl liners in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%.

Product detail pictures:

Related Product Guide:

We have our own product sales staff, style crew, technical group, QC staff and package staff. We now have strict high quality management procedures for each approach. Also, all of our workers are experienced in printing subject for Sand Making Machine Factories – MANTLE-GOOD AFTER-SALES SERVICE – Jinhua , The product will supply to all over the world, such as: Atlanta, Milan, Guinea, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!